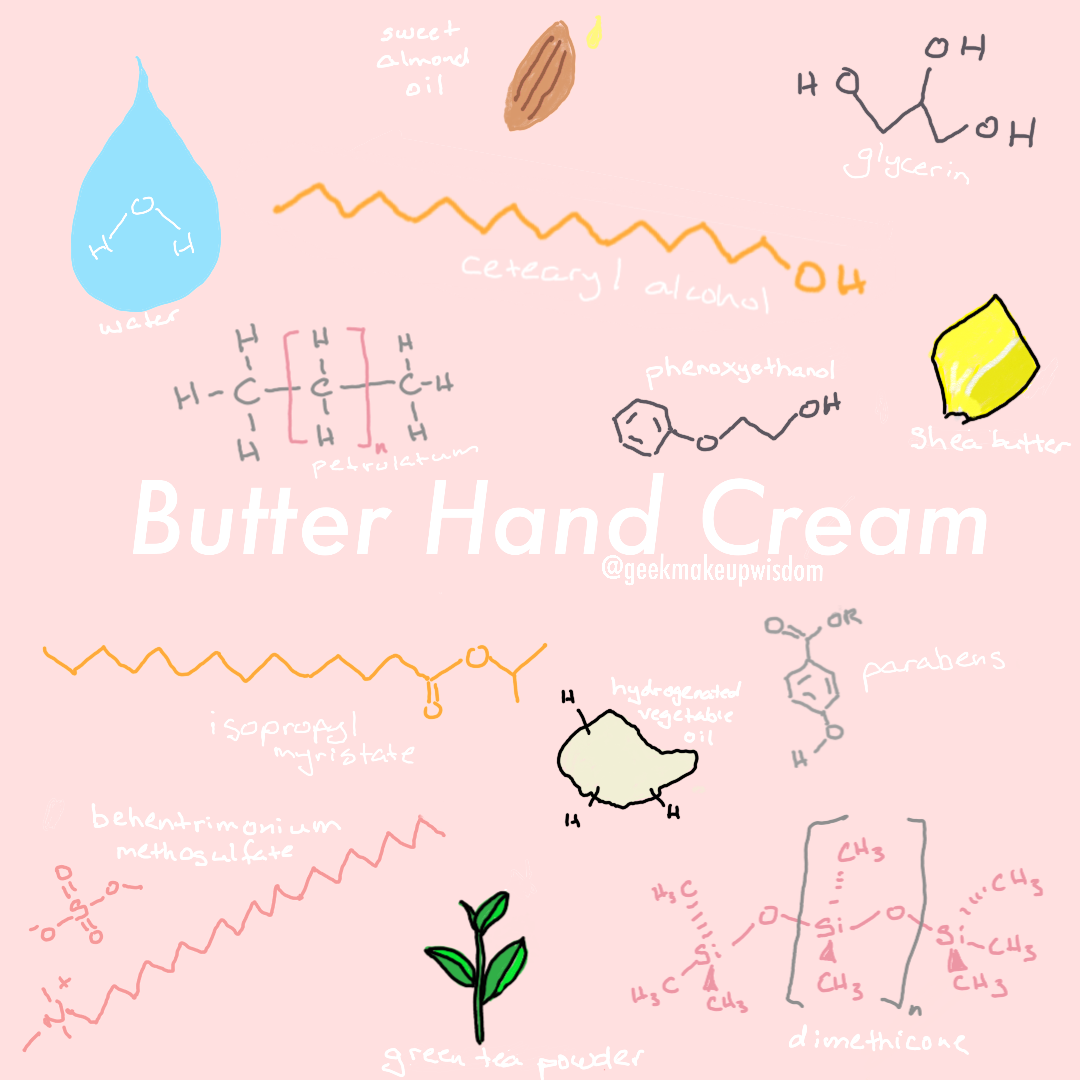

As an experiment, I was curious to see if I could feel a difference between shea butter and green tea butter. I got the green tea butter from MakingCosmetics.com. It’s a proprietary blend of sweet almond oil, hydrogenated vegetable oil, and green tea powder. I was intrigued to buy it not for any scientific reason, but simply because I just love green tea everything. So why not make a cream with green tea butter!?

I originally was riffing off of the Aveeno Body Lotion you can buy from Costco. My husband mentioned that he really liked that lotion, so I thought hey, let’s see what happens when you add butter! Except...I had a really mindless moment and misread the dimethicone as “12%” instead of “1.2%.” Oh well! I ended up making two very nice body creams with great moisturization. They are non-pourable, but I think they’d still be able to squeeze through a tube well. I’d actually like each of these as a hand cream!

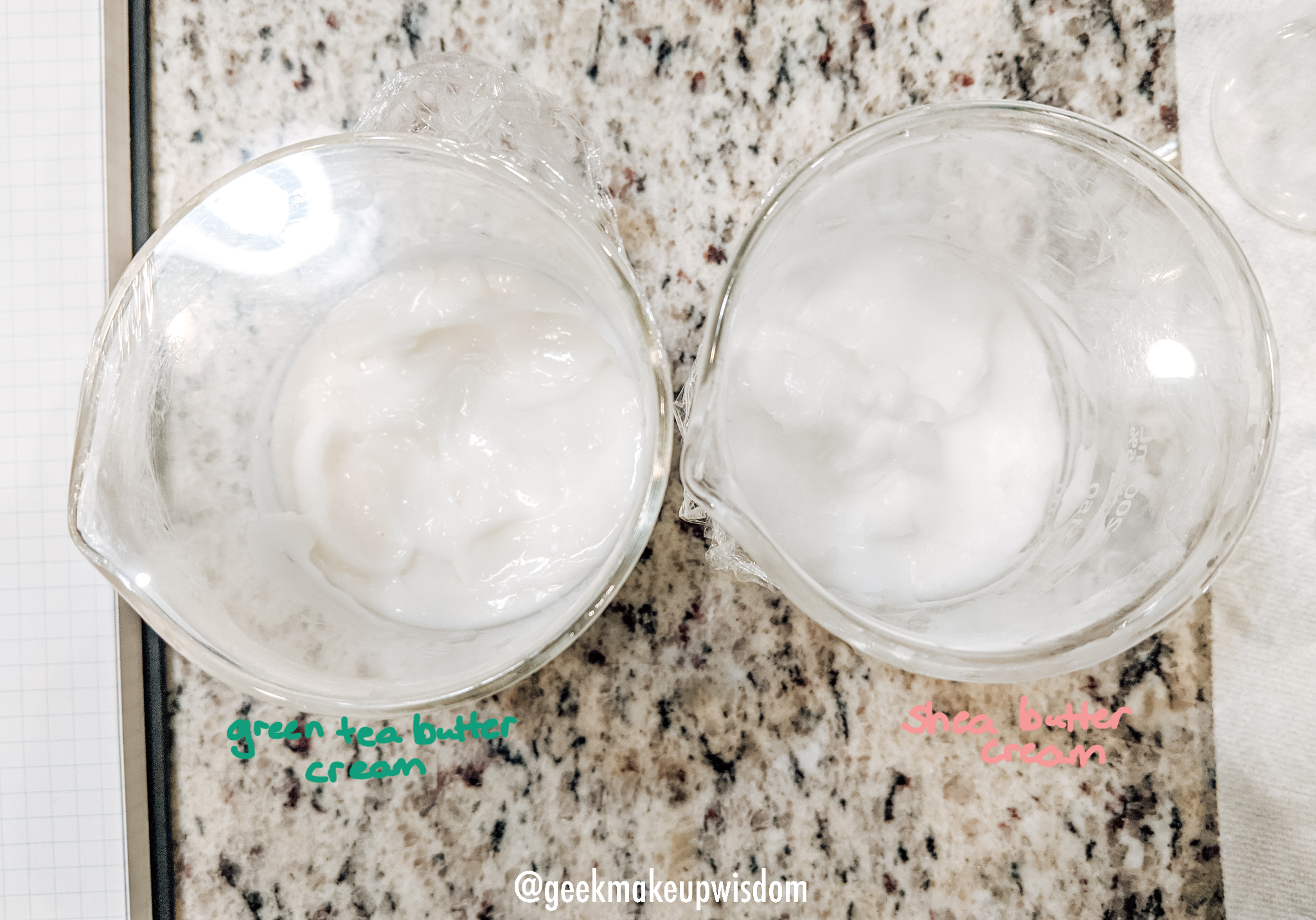

Any perceivable differences?

Now for the differences. Right away, the green tea butter formula has a light yellow (not green) color to it while the shea butter is a classic white cream. The two formulas do have a distinct difference in smell because of the butters as well. I don’t have a strong opinion on neither the color nor the smell. (If you’re thinking that the green tea butter would have a nice matcha smell, you’ll be greatly disappointed.)

I wanted to measure differences in pH, but my pH meter broke (yay…). I suspect that I wouldn’t find a difference in pH though since the water phase between the two formulas are the same. I don’t see how the difference in butters could affect the pH.

I couldn’t really feel a difference in aesthetics. The only thing that I noticed was that the green tea butter formula had a slightly better spread and longer playtime compared to the shea butter, which would make sense considering the fact it has sweet almond oil. Sweet almond oil (Virgin, unrefined) on its own isn’t the greasiest feeling of oils, but its conclusion in a butter mixture I’m sure would offer more glide than just the shea butter alone. Therefore it makes sense that I feel this difference between green tea butter and shea butter.

I asked my husband to do a blind test of the creams, and he felt the same way as me! In addition, he commented on how he didn’t like the shine after application of the green tea butter cream. “Why the hell would that matter? It’s a hand cream,” I told him. Him and his two friends then told me that they felt that a lot of men, including themselves, don’t like to be shiny anywhere. My husband’s verdict was that while he prefers the application of the green tea butter cream, he preferred the shea butter one simply because it left a matte appearance.

Chemical Differences

The sweet almond oil in green tea butter and shea butter have very similar fatty acid compositions, therefore the perceived difference in feel comes down to the composition of the hydrogenated vegetable oil and camellila sinensis leaf powder. Hydrogenated vegetable oil on its own is a waxy solid, so this is what makes the green tea butter a solid since the sweet almond oil is a liquid. I can’t imagine the green tea leaf powder was incorporated in high amounts.

Hydrogenated vegetable oil can also have different compositions. One blend I found contained a combination of palm kernel oil and cottonseed oil. Another blend I found contained African palm oil and wild cabbage oil. Since the green tea butter is a proprietary blend, I have no idea what the composition of the hydrogenated vegetable oil is. Hence, let’s take a look at just the differences between the fatty acid compositions of sweet almond oil vs shea butter.

They both have appreciable amounts of oleic acid in their compositions, but sweet almond oil’s second most abundant fatty acid is linoleic acid while shea butter’s second most abundant fatty acid is stearic acid. This helps to explain why shea butter is a solid while sweet almond oil is a liquid. The stearic acid amount helps to solidify the shea butter since stearic acid is a saturated fatty acid. (As a reminder, saturated means it has no double bonds.) Saturated fatty acids tend to be able to occupy more space in a volume since their single bonds allow them to “stack” more than double-bonded chains, even as part of a triglyceride. Linoleic acid has two double bonds as indicated by the “2” in “18:2.” This means that it’s a chain with 18 carbons and two double bonds. The double bonds cause the carbon chain to be bulky, so it’s harder to fit as many linoleic acids in a space than stearic acid. Thus, this makes sweet almond oil a liquid rather than a solid.

Don’t forget that these fatty acids are grouped up into triplets to form different triglycerides! Depending on the supplier, you’ll find that your triglycerides may have a very small amount of free fatty acid content, but for the most part they’ll be a part of a triglyceride. It was too difficult to put into a table the most common triglyceride combinations for shea butter since it can interestingly vary by region of origin! So instead, I think it’s more interesting to me to look at the fatty acid composition.

While writing this blog post, I started diving into the benefits of green tea on skin. I think that will be my next post since I really started to go down the rabbit hole with that topic. I will stop here for now and leave you with the formula above to play around with for your own uses. Let me know in the comments if you tried out this formula and what you thought of it!

FORMULA/PROCESSING INSTRUCTIONS

1. Combine Phase A in your main manufacturing vessel. Mix until a clear solution is obtained.

2. Combine Phase B in a separate container. Heat up the phase to 75 - 80 °C until solids are melted and incorporated. (Phase will be slightly opaque.) Maintain heat for emulsification.

3. Heat Phase A to 75 - 80 °C for emulsification.

4. Pour Phase B into Phase A with vigorous mixing (preferably homogenization) to incorporate the phases together and make a uniform emulsion.

5. Cool down the main manufacturing vessel to 40 - 45 °C with gentle mixing (propeller or hand-mixing will do depending on your scale). You can use an ambient to cold water bath to help cool the phase down.

6. Combine Phase C in a separate container and slowly add it to the main manufacturing vessel. Mix until a uniform emulsion is obtained.

7. Cool the formula down to ambient temperature (<30 °C).

8. q.s. with DI water as necessary.